The manufacturing industry is undergoing a significant transformation driven by the need for greater efficiency, agility, and innovation. Modern manufacturers face challenges such as supply chain disruptions, fluctuating market demands, and the pressure to adopt sustainable practices—all while maintaining profitability and competitiveness.

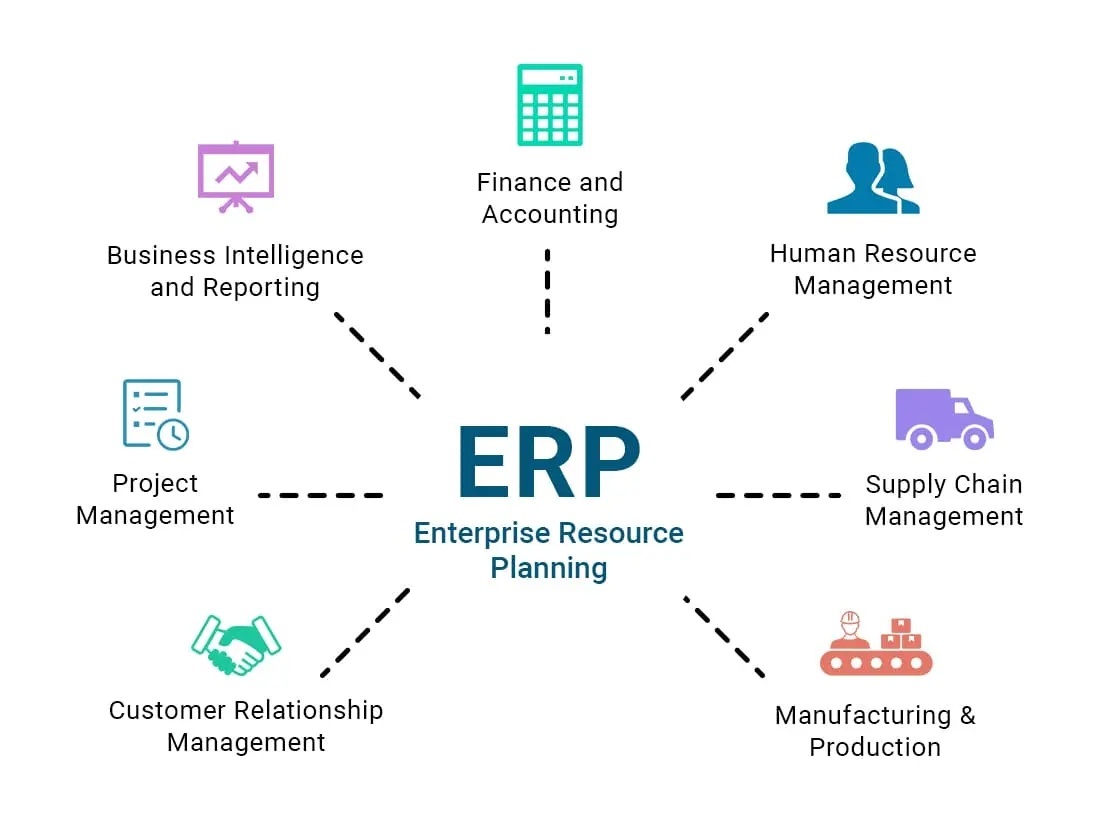

Microsoft Dynamics 365 offers a comprehensive solution tailored to the unique needs of manufacturers. By integrating enterprise resource planning (ERP), customer relationship management (CRM), and advanced analytics into a single ecosystem, Dynamics 365 empowers manufacturing businesses to operate smarter, adapt faster, and deliver better results.

In this article, we’ll explore how Dynamics 365 transforms the manufacturing sector by streamlining processes, improving decision-making, and driving growth.

Key Challenges in Manufacturing

Before diving into how Dynamics 365 helps manufacturers, it’s important to understand the common challenges the industry faces:

- Complex Supply Chains: Global supply chains are becoming increasingly intricate, with disruptions posing significant risks to production schedules.

- Fluctuating Market Demands: Manufacturers must respond to changing customer needs and market conditions while maintaining efficiency.

- Operational Inefficiencies: Legacy systems and manual processes often hinder productivity and scalability.

- Sustainability Pressures: There’s a growing demand for eco-friendly practices and compliance with environmental regulations.

- Labour and Skills Gaps: Manufacturers struggle with workforce shortages and the need to upskill employees for modern technologies.

Dynamics 365 addresses these challenges head-on by providing tools to optimise operations, enhance visibility, and enable innovation.

How Dynamics 365 Empowers Manufacturers

1. Streamlining Operations with Unified ERP and CRM

Dynamics 365 integrates ERP and CRM functionalities into a single platform, enabling manufacturers to manage their entire business from production to customer relationships. Key benefits include:

- End-to-End Visibility: Real-time insights into inventory, production schedules, and financials allow for better planning and decision-making.

- Order Management: Automate order processing, track shipments, and improve fulfilment accuracy.

- Integrated Sales and Service: Equip sales teams with the tools to manage accounts, track opportunities, and build stronger customer relationships.

By unifying operations, manufacturers can reduce complexity and operate more efficiently.

2. Optimising Supply Chain Management

Supply chain resilience is critical for manufacturers. Dynamics 365 Supply Chain Management helps:

- Enhance Visibility: Gain real-time insights into supply chain performance, identify bottlenecks, and respond proactively.

- Predict and Prevent Disruptions: Use AI and machine learning to forecast demand, predict potential disruptions, and optimise stock levels.

- Improve Supplier Collaboration: Strengthen relationships with suppliers through shared data and streamlined communication.

With these tools, manufacturers can build more agile and responsive supply chains.

3. Improving Production Efficiency

The Dynamics 365 suite includes features designed to optimise manufacturing operations:

- Production Scheduling: Advanced scheduling tools ensure resources are allocated efficiently, minimising downtime and waste.

- Shop Floor Automation: Integrate IoT devices to monitor machinery, track production in real-time, and reduce manual interventions.

- Lean Manufacturing: Adopt lean principles to streamline workflows, eliminate waste, and maximise output.

By improving production processes, manufacturers can reduce costs and enhance profitability.

4. Enabling Smart Maintenance with IoT and AI

Dynamics 365 Field Service and IoT intelligence enable predictive and proactive maintenance:

- Predictive Maintenance: Use IoT sensors to monitor equipment health and predict potential failures before they occur.

- Optimised Technician Scheduling: AI-driven scheduling ensures the right technician with the right skills is dispatched efficiently.

- Remote Monitoring: Reduce downtime and improve productivity by identifying issues remotely and resolving them quickly.

These capabilities minimise unplanned downtime, extending the lifespan of equipment and improving overall operational efficiency.

5. Enhancing Customer Engagement

In today’s competitive landscape, customer experience is as critical in manufacturing as it is in retail. Dynamics 365 helps manufacturers:

- Personalise Customer Interactions: Use data-driven insights to understand customer needs and tailor offerings.

- Streamline After-Sales Service: Offer exceptional support through automated case management and self-service portals.

- Improve Demand Forecasting: Leverage AI to predict customer demand, enabling better production planning and inventory management.

By fostering stronger relationships, manufacturers can boost customer loyalty and satisfaction.

6. Driving Innovation with Data and Insights

Manufacturers generate vast amounts of data across their operations. Dynamics 365 harnesses this data to unlock insights:

- Real-Time Analytics: Use Power BI and Dynamics 365 to create interactive dashboards, monitor KPIs, and track performance.

- AI-Driven Decision-Making: Predict trends, optimise pricing, and identify new opportunities for growth.

- Innovation Management: Streamline the development of new products with integrated project management tools.

With data at their fingertips, manufacturers can make informed decisions that drive innovation and competitiveness.

7. Supporting Sustainability Goals

Sustainability is becoming a key focus for manufacturers. Dynamics 365 enables:

- Resource Optimisation: Monitor energy usage, reduce waste, and improve production efficiency.

- Carbon Footprint Tracking: Use advanced reporting tools to measure and minimise environmental impact.

- Compliance Management: Stay on top of regulatory requirements with automated tracking and reporting features.

By aligning operations with sustainability goals, manufacturers can meet consumer expectations and reduce costs.

Real-World Success Stories

1. Automotive Manufacturer

A leading automotive manufacturer used Dynamics 365 Supply Chain Management to gain better visibility into its global supply chain. By leveraging AI-driven forecasting, the company reduced stockouts by 25% and improved on-time delivery rates.

2. Industrial Equipment Producer

An industrial equipment producer adopted Dynamics 365 Field Service with IoT integration to enable predictive maintenance. This reduced equipment downtime by 30%, saving the company millions in lost production time.

3. Food and Beverage Manufacturer

A food and beverage company used Dynamics 365 Finance to automate financial reporting and streamline compliance processes. This saved hundreds of hours in manual work and improved financial accuracy.

Why Choose Dynamics 365 for Manufacturing?

Dynamics 365 stands out as a solution for manufacturers due to its:

- Scalability: Tailored for businesses of all sizes, from small manufacturers to global enterprises.

- Integration: Works seamlessly with Microsoft tools like Power BI, Teams, and Azure.

- Customisation: Adaptable to specific industry needs through custom workflows and extensions.

- Security: Built on Microsoft’s secure cloud platform, ensuring data integrity and compliance.

Conclusion

The manufacturing sector is evolving rapidly, and businesses must adopt modern technologies to remain competitive. Microsoft Dynamics 365 provides manufacturers with the tools to streamline operations, optimise supply chains, improve customer engagement, and drive innovation.

By leveraging AI, IoT, and advanced analytics, manufacturers can overcome industry challenges and achieve sustainable growth.

If you’re ready to transform your manufacturing operations, Finsys Apps can help. Contact us today to learn how Dynamics 365 can empower your business to thrive in a competitive market.